Page 1 of 1

Spark Plug angle

Posted: 07 Oct 2025 17:02

by ericwwreckless

Does anybody know the angle of the spark plug relative to the head in these engines? I need it for a milling machine setup.

Re: Spark Plug angle

Posted: 09 Oct 2025 20:32

by ericwwreckless

Anybody?!

Re: Spark Plug angle

Posted: 15 Oct 2025 12:53

by tfel63

I feel the need to fill the void but without any practical advice of any substance! Would some sort of engineering protractor-type thing work?

Re: Spark Plug angle

Posted: 15 Oct 2025 15:14

by Glennh

Re. your spark plug angle.

Assuming you have another cylinder head with a good plug thread, why not machine the insulation from a spark plug, bore the spark body to take a suitable straight rod, insert aforemtioned rod through spark plug body and clamp the rod in the chuck on the mill. Then position suitable blocks/wedges under cylinder head face and fix them in position. Remove good cylinder head and rod from mill and replace with duff head. Spark plug angle will have been established via previous steps.

I recall a similar method was used for exhaust thread repairs and there is a you-tube clip showing the procedure.

Re: Spark Plug angle

Posted: 15 Oct 2025 16:11

by Vitesse

No idea but you could ask on one of the Whatsapp groups. Benjy and a few others can't help themselves but answer all the obscure questions!

Edit I've asked and nobody knows. That's why you've had no answer.

General view is to either insert threaded bar and measure it or, as the heads are flat, just mounting in a mill and set the angle to what is currently there. Most people use Timesert or specific plug thread repair kits.

Re: Spark Plug angle

Posted: 15 Oct 2025 18:40

by Steve Brown

Is this actually for a plug thread repair? Or some other job? It might help you get the info you need!

Re: Spark Plug angle

Posted: 15 Oct 2025 22:05

by ericwwreckless

A flurry of responses - thank you comrades. The repair is on a (new to me) Kanguro cylinder head where the timesert wound out with the plug when I was changing plugs. Since a new timesert won't work alone, it needs opening up and an aluminium insert fixed in place before the new timesert. Much more hassle than I would have liked from my new bike!

Re: Spark Plug angle

Posted: 15 Oct 2025 22:16

by MickeyMoto

Why not just fit an aluminium insert and tap that?

Re: Spark Plug angle

Posted: 15 Oct 2025 22:21

by ericwwreckless

That's probably what will happen, it would be easier knowing the original angle. I thought I had copies of the technical drawings but I 'misremembered'.

Re: Spark Plug angle

Posted: 15 Oct 2025 22:23

by ericwwreckless

Glennh wrote: ↑15 Oct 2025 15:14

Re. your spark plug angle.

Assuming you have another cylinder head with a good plug thread, why not machine the insulation from a spark plug, bore the spark body to take a suitable straight rod, insert aforemtioned rod through spark plug body and clamp the rod in the chuck on the mill. Then position suitable blocks/wedges under cylinder head face and fix them in position. Remove good cylinder head and rod from mill and replace with duff head. Spark plug angle will have been established via previous steps.

I recall a similar method was used for exhaust thread repairs and there is a you-tube clip showing the procedure.

Top tip - thanks.

Re: Spark Plug angle

Posted: 16 Oct 2025 06:06

by 3potjohn

One a different bike, with very accessible cylinders, I used a Spark Plug repair kit from UniThread to fit a wire insert. I used Loctite 266 and left it a few days. You have to break the insert tang off which I did in situ but captured it with a strong magnet on the tool at that moment. I have had inserts wind out on other minor repairs but my own fault for not allowing full cure of the loctite, so the bolt bonded.

Re: Spark Plug angle

Posted: 16 Oct 2025 18:46

by Steve Brown

I used to think adding loctite to wire inserts was a good idea. Then when talking to a rep from Loctite, and he was particularly speaking about their new anaerobic range of thread locks, he said not to use it as the agent will leak through and grip the plug or bolt/stud. This will make the insert come out next time the plug/fastener is removed. He also said what the Rolls Royce reps told us about helicoils, the hole should be scrupulously cleaned (the fresh cut thread for the insert) using brake cleaner etc. This will allow the wire insert to work as designed and grip the parent material. I use Recoil and Uni-thread inserts regularly and following this advice they don't need looking at again.

Timeserts are another good solution but cost more and I think need more surrounding diameter of parent material.

Re: Spark Plug angle

Posted: 17 Oct 2025 17:12

by 3potjohn

That info about Loctite is interesting.

Re: Spark Plug angle

Posted: 17 Nov 2025 09:03

by Parker3865

A bit late but...

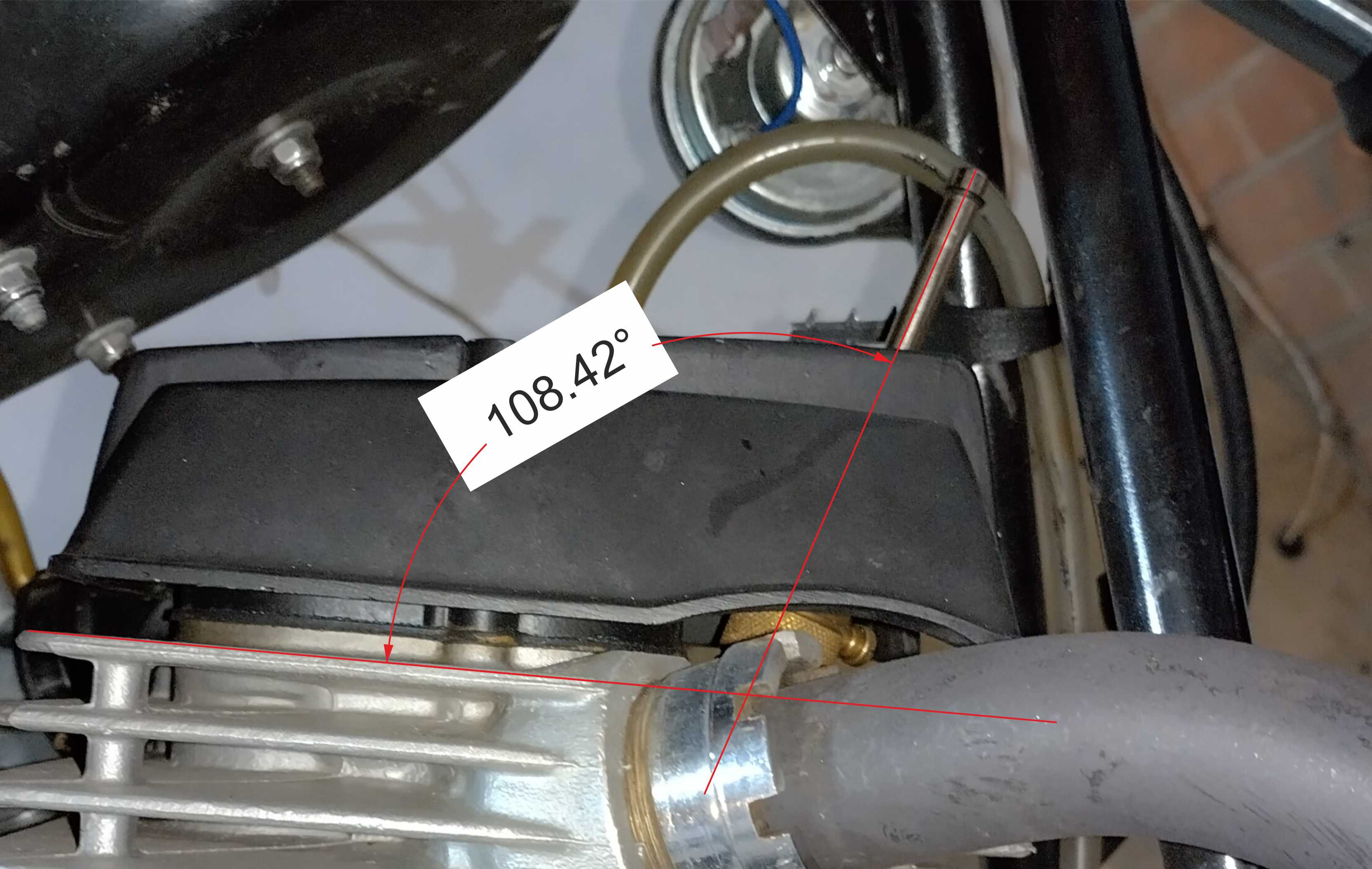

I had the plug out of my 250 2c and used a piston depth gauge. Photo and some CAD for the following:

- 20251114 Plug to head angle sm.jpg (355.73 KiB) Viewed 862 times

There will be some inaccuracy due to drawing the lines and parallax with the angle I held the phone at, but may help someone in the future.