Page 1 of 1

Crankshaft primary gear/oil pump gear removal

Posted: 17 Nov 2015 17:40

by 72degrees

So I'm stripping down the spare 350 motor that has been under the bench for years. It was running when removed but in a most un-Morini like way once released from the frame it started to leak between the crankcases. I'm hoping to fit an L5 cam so it had to come apart anyway. Cunning tricks have got the cam pinions off. I can fabricate a holding tool for the crank gear in the same fashion that I made a rotor holding device years ago but how vital is special tool 004. I can see that it provides some protection for the end of the crank but wouldn't a 27mm 6 point deep drive socket used carefully to the job?

Re: Crankshaft primary gear/oil pump gear removal

Posted: 17 Nov 2015 18:31

by 72degrees

Aha, now I see that the ring nut has already been removed and a more conventional (perhaps nyloc) nut used. Does this look like the usual replacement?

Re: Crankshaft primary gear/oil pump gear removal

Posted: 17 Nov 2015 20:23

by morinipete

Hi,

I think they went on the early motors. I've got a bag of brand new ones I got from Phil Smith's old stock. I think the funny round one, needing the special tool, came later? Perhaps they went to the round nut to avoid any internal clearance issues?

Pete

Re: Crankshaft primary gear/oil pump gear removal

Posted: 17 Nov 2015 21:01

by 72degrees

morinipete wrote:Hi,

I think they went on the early motors. I've got a bag of brand new ones I got from Phil Smith's old stock. I think the funny round one, needing the special tool, came later? Perhaps they went to the round nut to avoid any internal clearance issues?

Pete

This is a 1977 so that maybe the case. Just going to have to use a surface drive socket and a breaker bar or a rattle gun together with a proper holder.

Re: Crankshaft primary gear/oil pump gear removal

Posted: 17 Nov 2015 21:41

by Steve Brown

I'd agree with Pete. My 350 had that type from new in 77 (76 model) and still has the same one fitted. Every time I remove it I check the grip of the nyloc section before re-using it. When I joined the RAF as a mechanic I was surprised they allowed re-use of self-locking nuts, but the manuals all specified a torque figure to overcome the resistance of the locking portion. You tested using a dial type torque wrench. I soon developed a 'feel' for how much grip was acceptable and at least can kid myself by finger tests.

Nothing has come loose yet, but it could be embarrassing or expensive if it did happen.

If Pete is willing to sell a couple I'd be in the market.

Also, I have always used regular sockets with enough depth to do this job, without any problems. As you say, just check clearance and proceed with due care.

Re: Crankshaft primary gear/oil pump gear removal

Posted: 21 Nov 2015 17:12

by 72degrees

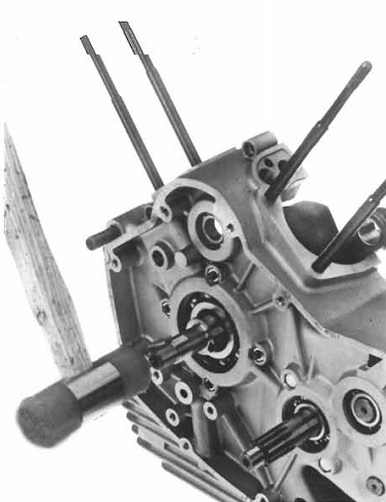

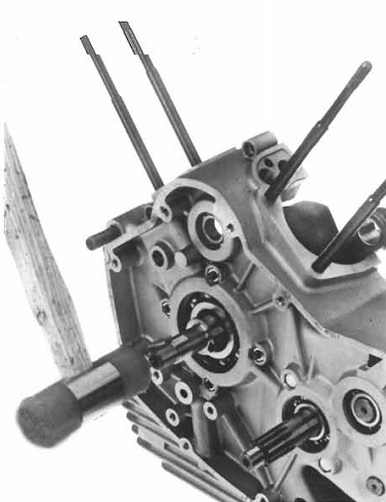

Well the nut is off. The NLM supplied special tool was cunningly located in my wood working vice so that it couldn't move whilst the pegs nestled in the holes in the pinion. I applied an 8 point impact duty 1/2 inch drive socket on a breaker bar and heaved. What a relief when it shifted. The oil pump worm gear and crank pinion succumbed to a 2 leg puller and the final spacer freed after liberal dousing in penetrating fluid. The crank still won't separate from the main bearing inner race though. I've run out of Plusgas so it's soaking in a cocktail of lesser fluids pending a refreshment of TUITs. Think I'll deploy the BIG gas torch with Calor gas bottle I use for flame throwing the veg garden weeds to the bearing before I give it a squirt of Shock & Unlock and proceed as in this photo. I've not missed anything have I - just probably rusted on a bit?

Re: Crankshaft primary gear/oil pump gear removal

Posted: 21 Nov 2015 20:17

by EVguru

Undo the screws inside the case that hold the bearing retainer plate in place and take the crank out of the cases complete with bearing. Heat the case to help the bearing slide out.

Then you can use a puller on the bearing.

Re: Crankshaft primary gear/oil pump gear removal

Posted: 21 Nov 2015 20:26

by 72degrees

EVguru wrote:Undo the screws inside the case that hold the bearing retainer plate in place and take the crank out of the cases complete with bearing. Heat the case to help the bearing slide out.

Then you can use a puller on the bearing.

Ah, didn't realise you could get to them with the crank still in place. Sounds like a plan.

Re: Crankshaft primary gear/oil pump gear removal

Posted: 22 Nov 2015 14:25

by 72degrees

It's out. Took the retaining plate screws out but in the end, after a soak in Plusgas and getting the crankcase properly supported on wooden blocks so that I could use the Thor hammer persuader properly, after a good warm up and a blast of shock & unlock it finally started to move through the main bearing inner race.

The bad news, the one set of big end shells show significant wear and scoring and the journal is a tiny bit marked. I'm hoping it's not already been reground to the limit. I've decided to go for the conversion of plain main bearing to roller anyway, so I'll just throw the crank, rods and cases at NLM.

The budget for this project is growing alarmingly. I think I really will have to sell the Corsaro. It's probably got to go with a view to house down-sizing anyway.